Infusion tech – history

Vacuum resin infusion is considered a relatively recent process; it was filed in 1959 in U.S. for the production of swimming pools made in fiberglass (GRP, Glass Reinforced Plastic), using a system of distribution of the resin. In the early 80’s Lotus Cars used a similar process for the production of car body parts. In the same years, one of the first applications in the water was a series of RORC One Design yachts, produced by Jeremy Rogers in Lymington, England.

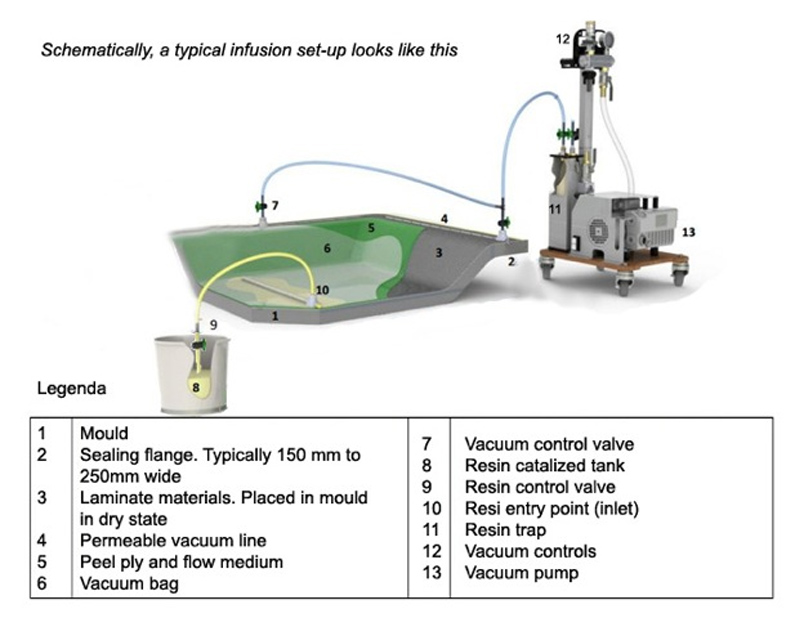

Main aspects of infusion:

Achievements of vacuum resin infusion

Process with low emissions of styrene and acetone

Process with low emissions of styrene and acetone Standardized and repeatable process and pieces

Standardized and repeatable process and pieces Excellent composite’s mechanical characteristics

Excellent composite’s mechanical characteristics Weight reduction

Weight reduction Time and costs reduction

Time and costs reduction

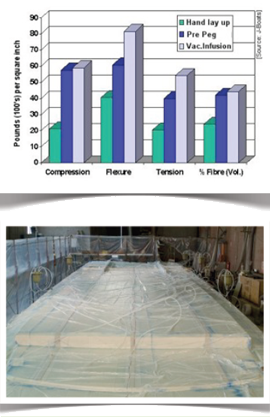

Infused Composite’s Quality

Excellent resin / fiber ratio (35%-65%)

Constant thickness

No use of putty or bonder for fixing the core

Absence of interlaminar air bubbles

Excellent mechanical properties of the laminate due to uniform compression exerted by vacuum.

Environment

Low emissions of styrene in the air

Low emissions of styrene in the air Cleanliness

Cleanliness Reduced costs for PPE and flue gas treatment equipment

Reduced costs for PPE and flue gas treatment equipment

Ergonomics

Ergonomics No contact with resin by workers

No contact with resin by workers Reductions occupational diseases (carpal tunnel, etc …..)

Reductions occupational diseases (carpal tunnel, etc …..)

Comparison with the main processes:

Attention: The internal data of table “2” is corrupted!